In Australia, electrical safety isn’t just a recommendation — it’s a critical legal and ethical responsibility. Whether you’re a business owner, a landlord, or managing a worksite, understanding and implementing proper electrical safety testing — particularly “test and tag” — is paramount. It’s about protecting lives, preventing injuries, and ensuring compliance with stringent Australian regulations.

We’ll walk you through everything you need to know.

The Australian work health and safety (WHS) landscape places a significant emphasis on preventing risks associated with electrical equipment. Fully-checked appliances and systems reduce the chance of:

Regular electrical safety testing, particularly test and tag, is your preventative strategy: catching hazards before they escalate, supporting insurer requirements, and creating a safer environment for everyone.

Test and tag is a systematic process of visually inspecting and electrically testing portable electrical equipment and flexible cords, then labelling each item with the outcome of evaluation. This tag includes:

The primary goal of test and tag is to identify any faults, damage, or wear that could make an item unsafe, and then clearly label or remove it, to ensure that only safe and compliant equipment is in service.

While specific requirements vary slightly between states and territories, generally, any workplace that uses electrical equipment — especially in areas of risk of electric shock — is legally obligated to ensure items are safe and maintained in good condition. Common sites include:

If people are using your electrical equipment, you have a duty of care to ensure items are safe — which includes regular inspection, testing, and tagging.

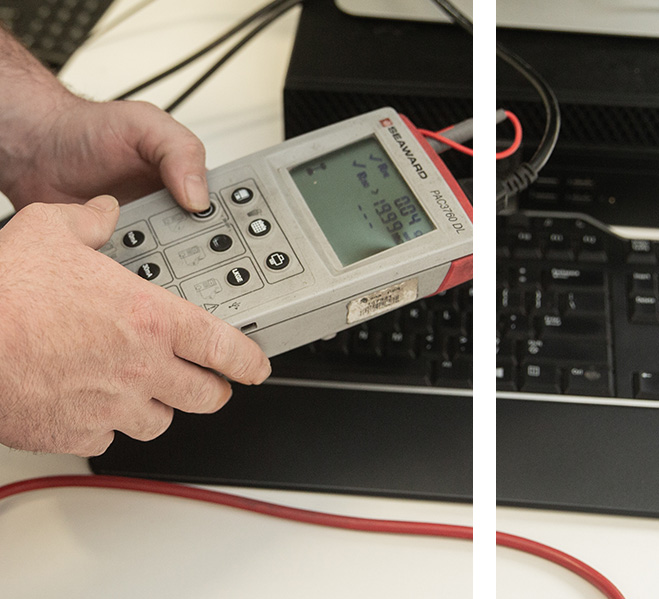

A qualified and competent person performs the test and tag process, typically following these steps:

The frequency of test and tag depends on the type of equipment, its usage environment, and the level of risk involved. Australian Standards AS/NZS 3760 (In-service safety inspection and testing of electrical equipment) and AS/NZS 3012 (Electrical installations—Construction and demolition sites) provide detailed guidelines.

It is crucial to consult the relevant Australian Standards and your state or territory's WHS regulations to determine the exact requirements for your specific industry and equipment.

In Australia, test and tag can be performed by a competent person. Typically this means someone who:

While some businesses choose to train an in-house person, many opt to engage professional test and tag services. Professional providers offer expertise, calibrated equipment, and efficient service, ensuring compliance without the internal resource burden.

Electrical safety testing, with test and tag at its core, is a vital component of responsible business operation and property management in Australia. It's not merely a tick-box exercise; it's an investment in the safety of your employees, customers, tenants, and assets.

By understanding the requirements, engaging competent professionals, and adopting a proactive approach, you can ensure a safe electrical environment and maintain full compliance with Australian regulations.

Don't compromise on electrical safety – it's too important.